As energy prices skyrocket and low carbon heating systems begin to replace traditional gas boilers, more and more people are exploring the option of having underfloor heating (UFH) installed in their homes.

Climate change is one of the greatest challenges facing the world. Huge cuts in greenhouse emissions are required by 2030, and beyond. Our homes and other buildings will need to operate at net-zero carbon capacity, at the very least.

The UK is already moving towards reduced carbon emissions through a number of initiatives; one of which being the banning of gas boilers in newbuild homes from 2025.

In the pipeline to replace gas boilers are low carbon heat pumps – such as ground source and air source heat pumps – powered by renewable energies and electricity, which will lead to changes to how we heat our homes.

UFH is the most viable heating option when gas boilers are phased out. The system only needs to run at between 35-40ºC in order to heat most rooms, making it perfectly compatible with ground source and air source heat pumps.

As a result, the increasing interest in UFH presents a major opportunity for installers, and the market is expected to grow significantly, as the shift towards eco-friendly heating gathers pace.

Selling the benefits

For the consumer, UFH offers some clear benefits. For example, it can heat a larger area at a lower temperature than a radiator, as well as being able to heat individual zones as they are occupied. This improves efficiencies and reduces bills.

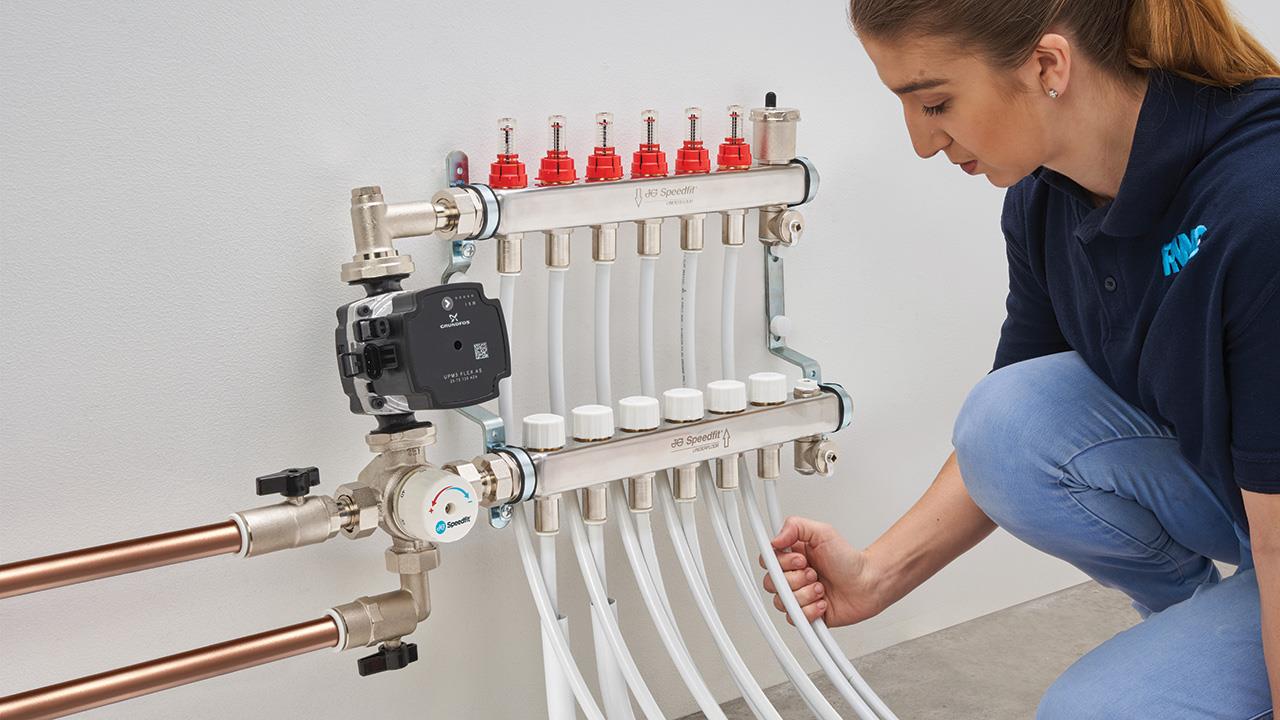

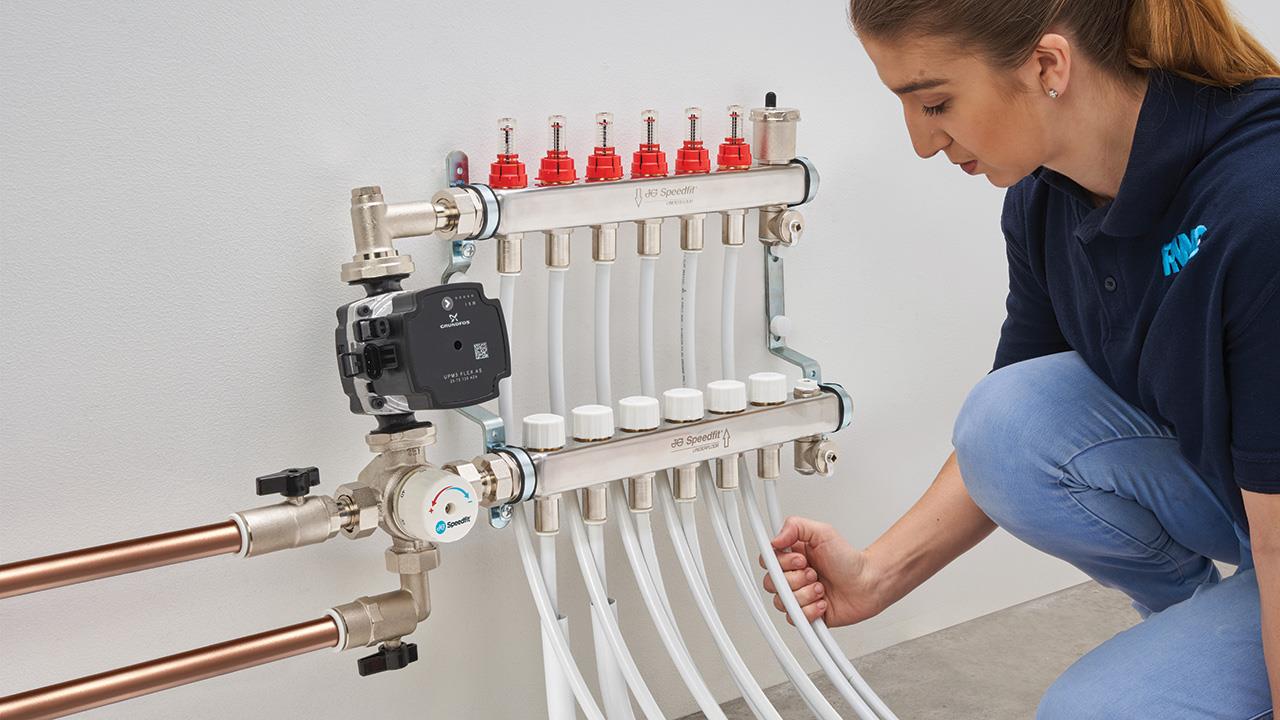

Additionally, most UFH systems can be paired with smart thermostats, giving users more control over their heating. With guarantees from manufacturers, like RWC’s 50 year guarantee on JG Underfloor pipework, UFH is ideal for those looking for high quality heating alternatives.

A further benefit of making a home more sustainable with solutions like UFH is improved aesthetics. With no need for radiators taking up wall space, UFH also offers more flexibility with interior design and room layout. This makes it ideal for open-plan areas, as well as compact homes where space is at a premium.

Planning your project

To some installers, fitting UFH may seem like a daunting task and you can come unstuck if you are not fully prepared. It can be a very costly and time-consuming job to rectify mistakes, such as if a system is incorrectly installed, or if a leak is found after the flooring has been laid.

The first step of any UFH installation is to thoroughly plan the project, to understand the floor construction and the space you are working with, so that the job runs smoothly.

For example, newbuild projects are likely to have a solid concrete floor covered by an insulation layer, which the UFH pipework will be fixed to before being screeded over. Finally, the floor finish goes on top of the screed.

Crucially, installers must remember that the insulation depth should comply with design or Building Regulations.

You will also need to understand the space you are working with, which will determine the pattern in which you lay the pipework, whether it’s serpentine or counterflow.

Serpentine is especially good for irregularly shaped rooms, such as kitchens with an island, or rooms with a bay window. Counterflow works well with square rooms.

Planning how the pipework is laid out should be done during the design stage. CAD drawings can be provided as long as the necessary level of floor layout detail is provided. Pipework needs to be fully measured so that enough materials are ordered. Flow rates need to be calculated to ensure there is sufficient water going through the pipes to heat the room effectively.

Many large UFH suppliers, including RWC, have support teams in place who can help with the planning and reduce the risks. Installers can share project details with our technical team to receive free CAD drawings and tailored advice specific to the heat source, floor type, and covering they are working with.

Ideal floor finish

UFH can be used with a variety of floor finishes, from carpet to vinyl and laminate, through to the most ideal finish – ceramic tiles – which, with a low tog value of around 0.1, allow for a more efficient heat transfer.

But be careful. Ceramic tiles can also be prone to cracking if the UFH is incorrectly installed, or if certain conditions are not met during the fitting, screeding, pressure testing, and commissioning process.

To further promote the use of UFH in a range of projects, we’re working on educating installers. Many are learning that it’s a surprisingly easy system to fit, and that it is possible to lay all the pipework in an average size house in just a day.

It seems clear that in the coming years the sector is going to see huge growth. The use of UFH has been building up over the last 10 years and it is now gathering further momentum, alongside the increasing adoption of renewable energy, as householders look for ways to make their homes more sustainable and cheaper to heat.

We are confident the market is going to keep building and building and, in the next decade, we confidently expect it to take over from radiators as the most common way of heating homes.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.