While electrical installation work makes up only 10-15% of the average project for a heating engineer, it can represent a much larger proportion of the headaches.

Fiddly and time-consuming electrical terminations can slow the installation down, and any that have not been completed as required can be hard to identify, causing further delays or snagging issues.

Electrical cable terminations are traditionally done using a terminal strip, the most utilitarian of generic products. They’re not difficult to use, but even the simplest of traditional techniques can be improved and, in this case, the use of lever or push-in connectors can save time, make the job easier, and help heating engineers achieve consistently compliant installations.

Barriers to change

Across all areas of the construction and fit-out sector, there is a tendency to remain loyal to the products and installation techniques we used when we were trained.

Despite working in a sector where continuous learning is integral to professional competence and compliance, this is just as true for heating engineers as it is for any other industry, particularly when it comes to tasks that make up only a small part of an installation, like making electrical terminations.

Ideal Industries is always on the look out for better, faster, and easier ways for customers to deliver projects. However, we recognise that expecting experienced professionals to change habits that have been ingrained over decades is like asking someone to ditch the sugar in their tea overnight. That’s why we’re working with colleges to support the next generation of heating engineers, offering complimentary lever and push-in connectors, so that they can practice using consumables that are faster, easier, and more consistent.

The other barrier to change, when it comes to switching from terminal strips to lever or push-in connectors, is perceptions of cost. While the unit price of connectors may be slightly more than terminal strips, the time savings they offer easily offset that minimal additional cost.

What’s more, making the switch provides peace of mind because use of connectors removes any inconsistency associated with the tightening of terminal strip screws, thereby building value into the cost of the connectors by reducing the need for quality assurance checks or call-backs.

Improving installation integrity

An installed cost purchasing strategy for delivering consistently safe and high quality installations by using lever or push-in connectors doesn’t only benefit contractors, it also delivers quality assurances for the customer.

Firstly, it ensures that installations are consistently safe and compliant with current wiring regulations. The 18th Edition wiring regulations require that traditional terminal strip connections should be accessible for annual inspections in compliance with BS EN 60670-22, which makes it difficult to select a suitable location for terminal strip connections, and leads to non-compliance issues for many projects.

Conversely, lever and push-in connectors are classified as maintenance-free when used in conjunction with an approved enclosure box, so can be part of a compliant installation anywhere within the property.

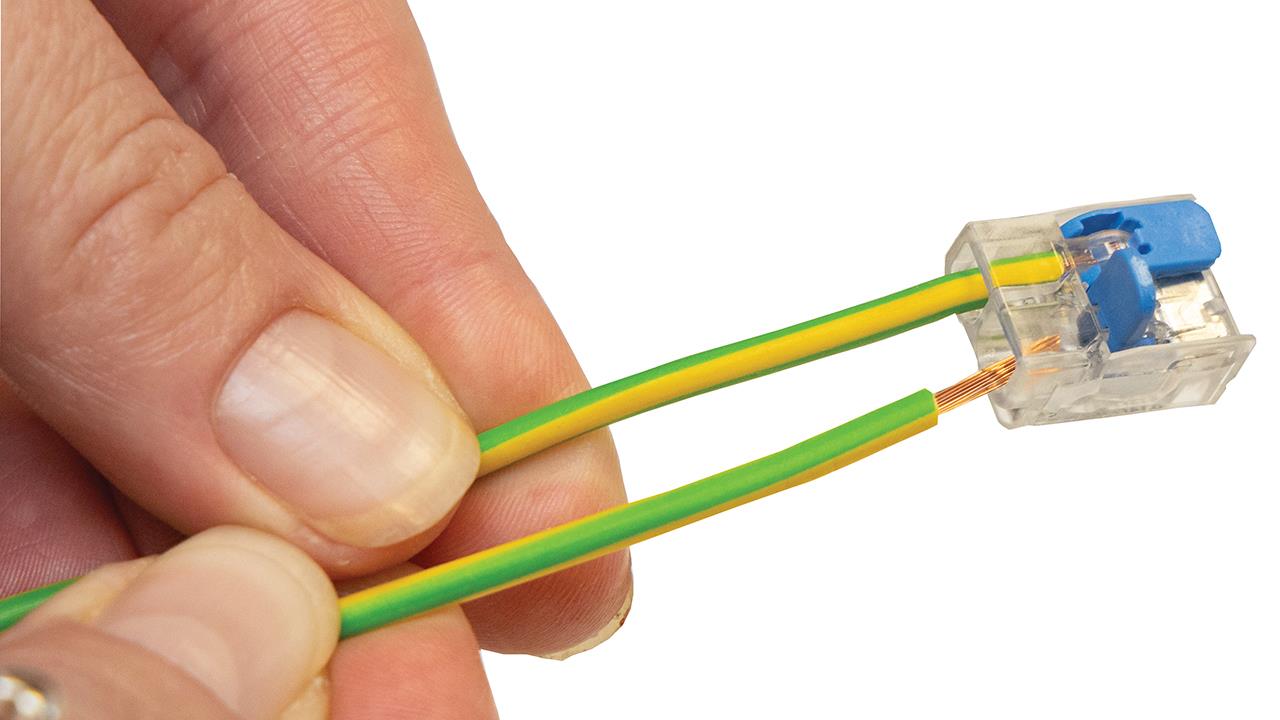

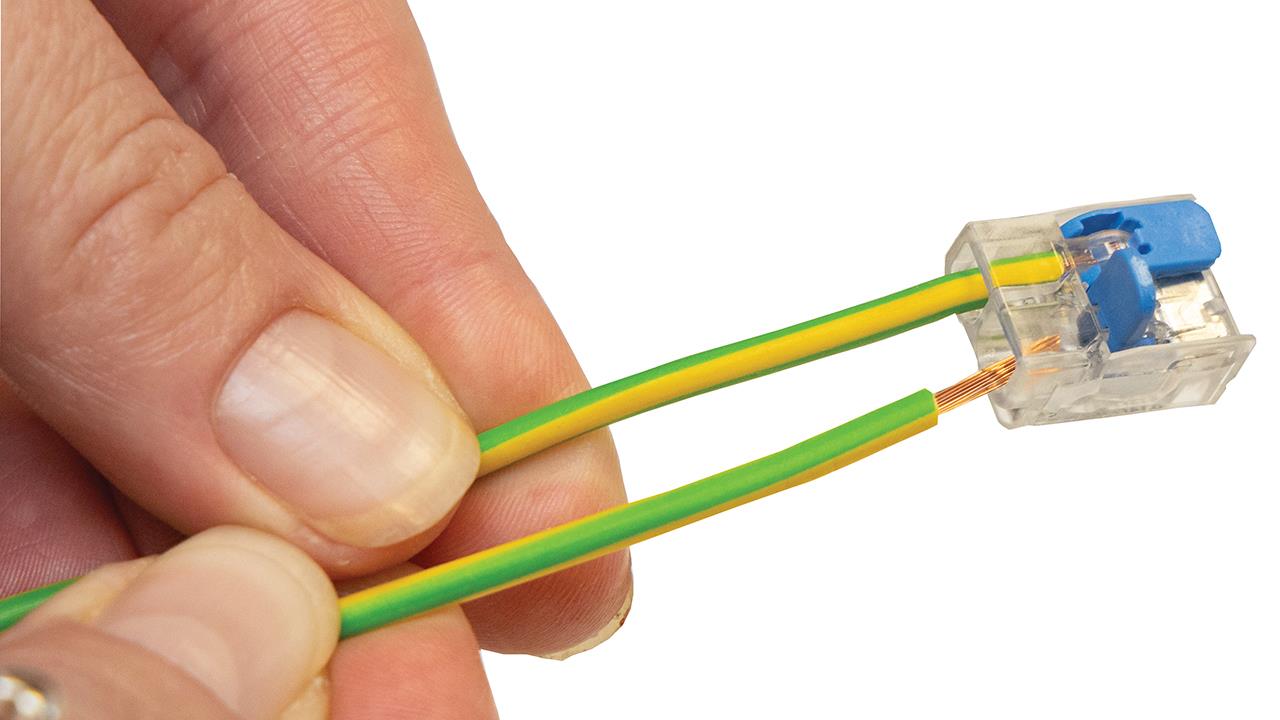

Secondly, using connectors, rather than terminal strips, ensures every connection is consistent because there is no variation in the tightening of the fixing screw that fastens the cable in place. Ideal Industries’ connectors even include a stripping guide on the side to aid consistently accurate stripping of the cable prior to connection, along with a CPC port for relevant testing.

This standardised approach to making connections ensures lever and push-in connectors deliver a fit-and-forget solution, as well as improved speed of installation.

While speed and consistency of terminal strip installations grows with experience, connectors remove any margin for error, even for those less experienced with electrics.

Developing opportunity

Lever and push-in connectors are not new, but neither are they static. Robust and well-designed at an attractive price point, lever and push-in connectors can offer a user-friendly, cost effective, and quality-led alternative to terminal strips.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.