To meet the growing demand for housing across the UK, the government has targeted the construction of 300,000 new homes every year. Within a landscape where sustainability is high on the agenda, these new homes provide an opportunity to create efficient buildings that have a minimal environmental impact while meeting the needs of occupants.

Plumbing and heating systems have a crucial role to play in this journey, with efficient systems helping to reduce energy consumption and conserve water – all while maintaining comfort and reliability to create homes that are fit for the future.

The changes to Part L of the Building Regulations, which came into effect in 2023, outline the specific requirements of plumbing and heating systems in new build properties. At the heart of these changes, gas boilers in new builds must deliver a 92% efficiency, while central heating systems should be sized for operation at a maximum of 55°C.

With these requirements directly impacting the construction of new homes, they unlock the potential to introduce plumbing and heating technologies that prioritise sustainability.

A shift in home heating

With around 30 million homes in the UK, it’s not surprising that heating them makes a significant contribution to overall emissions – around 17% in total. By rethinking how new homes are heated, efficiency, and sustainability can be directly improved.

From 2025, in accordance with the government’s Future Homes Standard, gas boilers will no longer be installed in new build homes, reducing reliance on gas. Instead, low emission alternatives like heat pumps will be used. For new build properties, adopting these emerging technologies is relatively straightforward as the buildings themselves can be designed to accommodate them.

In turn, this opens up the potential for change elsewhere in new homes, including the specification of underfloor heating (UFH).

Specifying underfloor heating for sustainability

Including UFH in the specification of new homes means that effective systems can form an integral part of the building from the outset. The low operating temperatures of these systems – typically between 40°C and 50°C – means they align directly with the requirements of today’s Building Regulations, placing sustainability at the heart of design.

While these operating temperatures ensure greater levels of efficiency are achieved, they also enable housebuilders to deliver homes that are fit for modern living.

When we think of traditional home heating, radiators will probably spring to mind as a solution that has been relied on for many decades. The problem with radiators is that they are energy hungry, requiring operating temperatures in excess of 65°C to adequately heat a room. Even then, cold spots are commonplace, compromising both efficiency and comfort. UFH changes this by transforming the entire floor space into a heater, unlocking greater comfort, efficiency, cost-effectiveness and even aesthetics.

With systems such as JG LowFit hidden beneath the floor, rather than taking up valuable wall space, room layouts can be more flexible, making them better suited to modern living styles. Similarly, UFH systems can be controlled using smart technology, giving occupants full control over their heating – and subsequently supporting ongoing sustainability.

Pipes and fittings for sustainable systems

Alongside the systems that can facilitate efficiency, specifiers also need to consider the materials used to make plumbing and heating systems truly sustainable. When building sustainability into new homes, the materials used will have a direct impact – not just during construction, but also throughout its decades in use. Selecting materials that can stand the test of time is crucial to long-term efficiency and reliability.

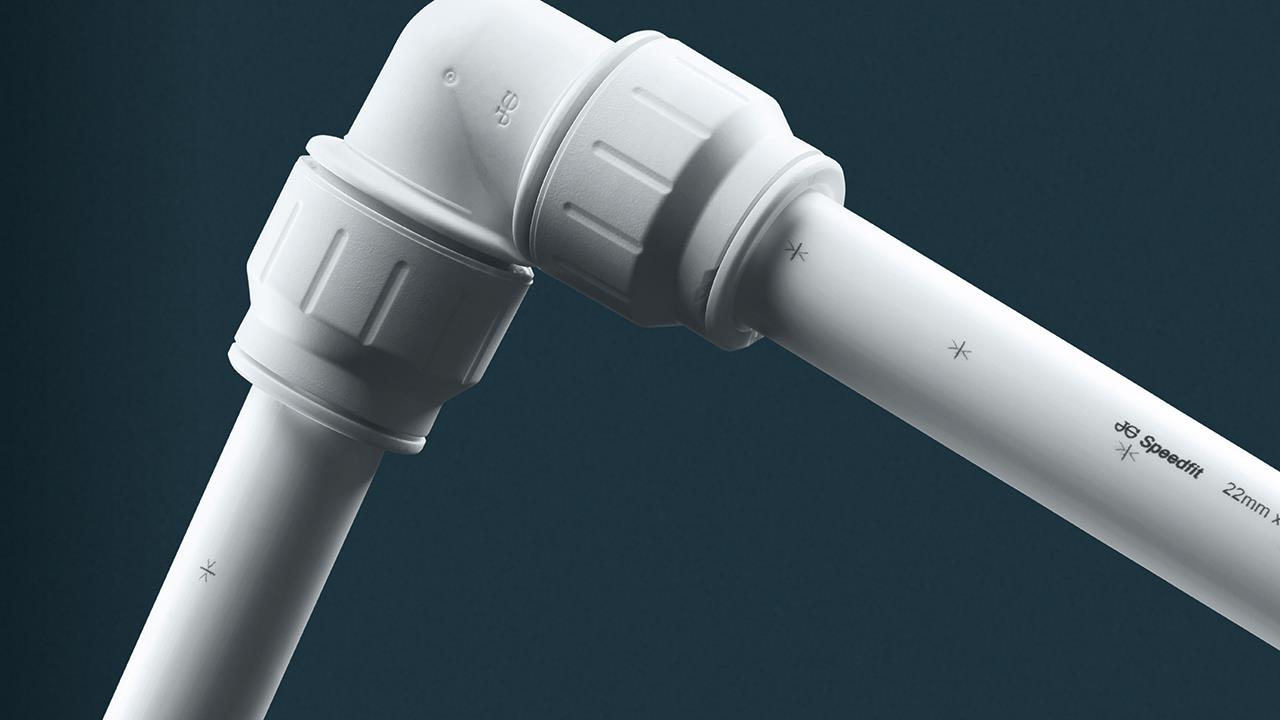

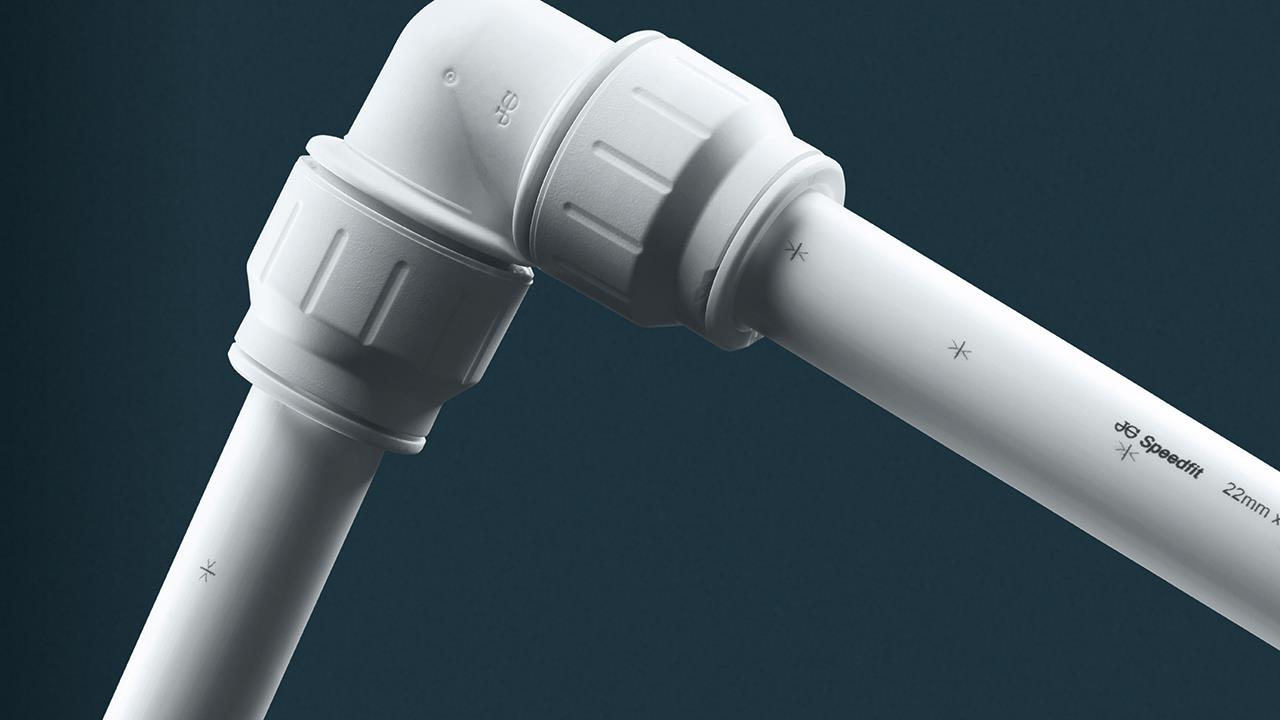

Plastic is a popular choice to underpin the long-term performance of plumbing and heating systems, with push-fit fittings – including those pioneered by JG Speedfit – leading the way. Suitable for a wide range of applications, JG Speedfit pipes and fittings can be used to create strong, efficient and reliable domestic plumbing and heating systems.

Featuring push-fit technology, solutions like plumbing manifolds can be used to create a central distribution point for hot or cold water, reducing the complexity of pipework and elevating efficiency. From the manifold, flexible plastic pipe such as JG Layflat, can be used to create long pipe runs without the need for additional connections, supporting long-term performance and minimising the potential for leaks.

Specifying plastic solutions for new build homes unlocks the potential to create future-proof plumbing and heating systems that prioritise sustainability and user comfort. The properties of plastic make components resistant to corrosion, ensuring they’ll last for decades. Paired with push-fit technology, these components can also be installed quickly and safely, without the need for tools or flames.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.