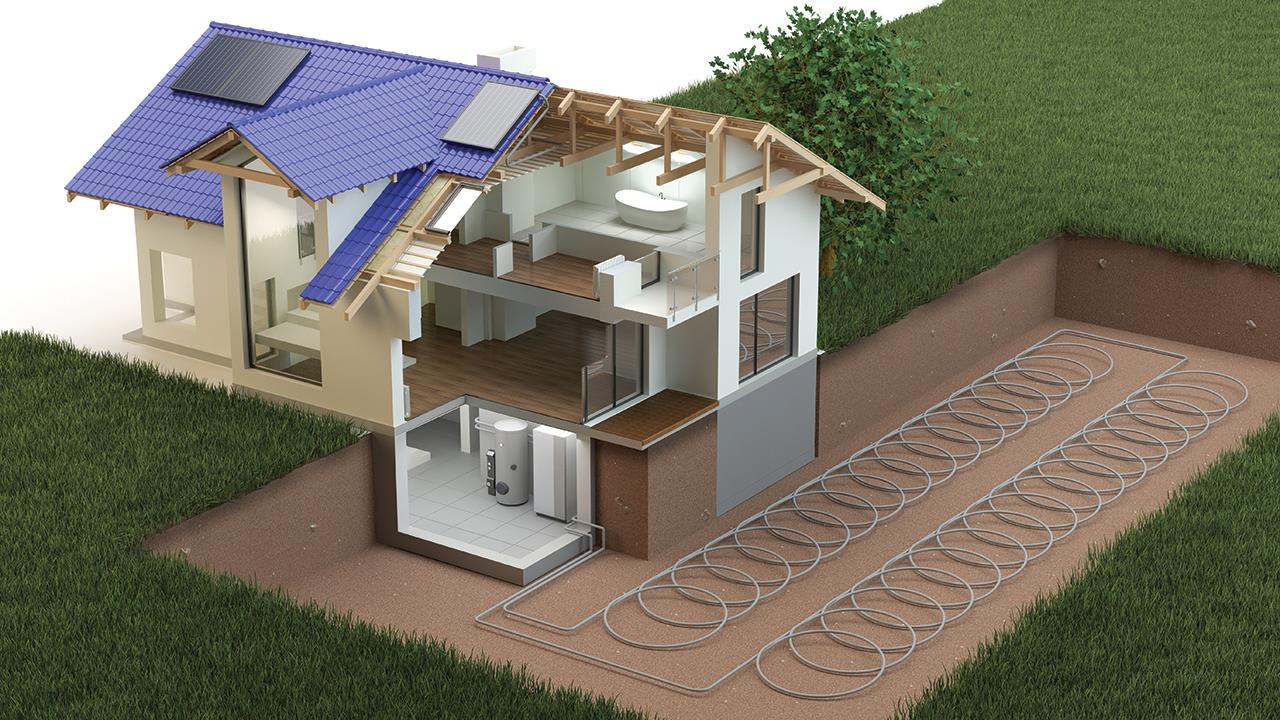

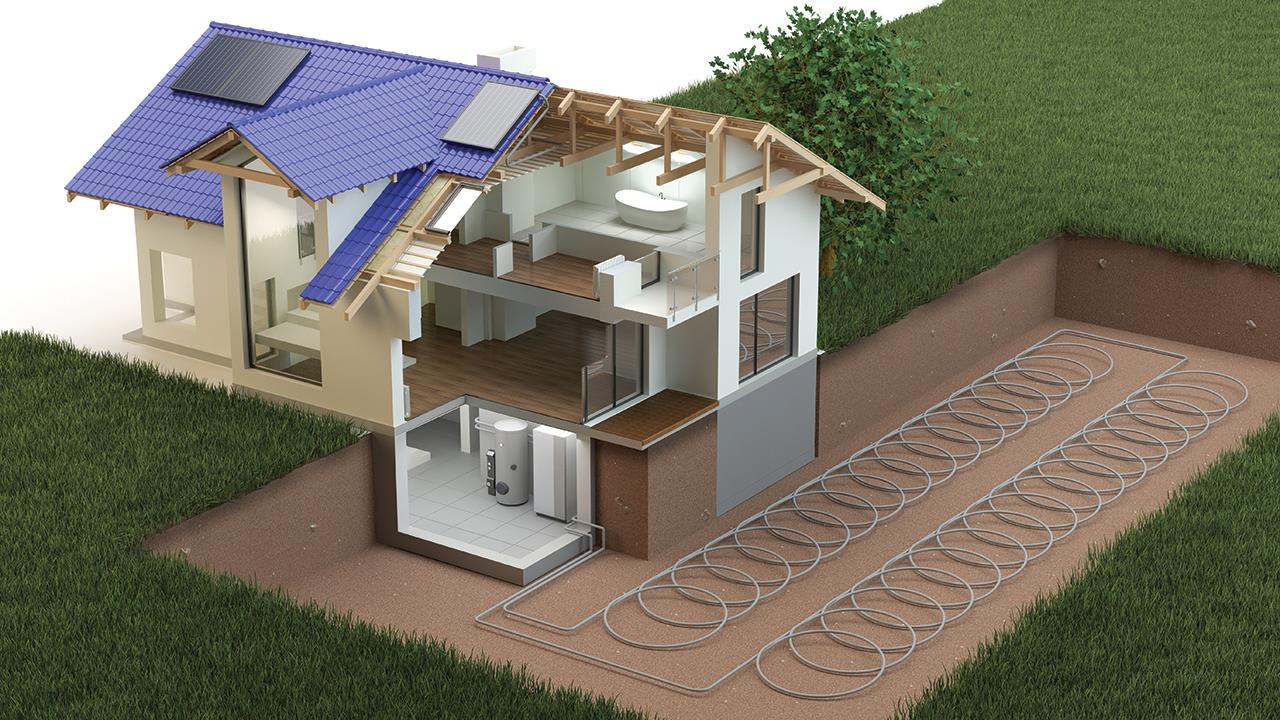

Heat pump installations are growing in popularity as they improve the efficiency of energy systems and can reduce bills. But they can be a costly investment that needs to be protected, meaning careful consideration should be given to selecting components that optimise and protect each part of the system.

Here we explore two components which, if installed correctly, can help do just that.

Anti-freeze valves

Anti-freeze valves are a cost-effective solution to protect heat pump installations from freezing, which is a common problem during the winter.

An anti-freeze valve is designed to be installed in the flow and return pipework from the heat pump and on the external pipework. By opening at temperatures below 3ºC, an anti-freeze valve allows system content to be dripped and discharged safely, preventing the system from freezing and protecting the installation. At temperatures above 4ºC, the valve shuts again to stop unnecessary draining.

Overall, it does exactly as it implies, it prevents the freezing of heat pumps and pipework. With the valve designed specifically for heat pump installation, it is compact and easy to install.

Even for installations in areas that are especially exposed – those that are usually hit hardest by freezing – an anti-freeze valve can continue to function efficiently. It becomes especially useful in the coldest months as it helps to save thousands of pounds by helping avoid the need to replace frozen installations by maintaining the heat pump and pipework.

Once protected, system performance can then be optimised. The efficiency within the system relies on the ‘start-up’ period of the heating cycle being correctly balanced, thus preventing it from drawing an excessive amount of energy. If a heat pump installation were to draw too much energy, the end-user would likely see a negative impact on the operation of the entire system.

Automatic dynamic balancing valve

Any system that has a heat pump as its energy source would benefit from installing an automatic dynamic balancing valve.

By accurately managing the flow rates throughout the heating circuit using a flow-settable, pressure independent thermostatic radiator valve (TRV), an installer can optimise their design and ensure each part of the system receives the correct amount of energy independently, thus increasing the working life of the compressor within the heat pump.

In addition, any hydronic circuit serving a secondary system must be balanced, meaning that it must be constructed in such a way as to guarantee the design flow rates of the thermal medium. Due to this, specific balancing devices can be required, depending on the type of system and appliances used.

Automatic dynamic balancing and pressure independent adjustment of the heating system is vital for the optimisation of a heat pump installation. A thermostatic radiator valve (TRV) can combine these different functions in a single component, in conjunction with a thermostatic, electronic, or thermoelectric control.

An automatic dynamic balancing TRV can balance the heating system automatically, ensuring each terminal receives the set flow rate. Even in the case of partial circuit closure, by means of the regulating valves, the flow rates in the open circuits remain constant at the set value – a vital feature on systems powered by heat pumps.

By using this type of TRV, in combination with thermostatic control heads, the surrounding temperature can remain automatically constant, thus guaranteeing effective energy saving.

Optimised system

The installation of an anti-freeze valve and an automatic balancing TRV will protect the end-user’s investment and the installer’s hard work. Given the installation costs of greener technologies compared to standard gas or oil installations, the benefits of a relatively small outlay to protect this investment are clear.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.