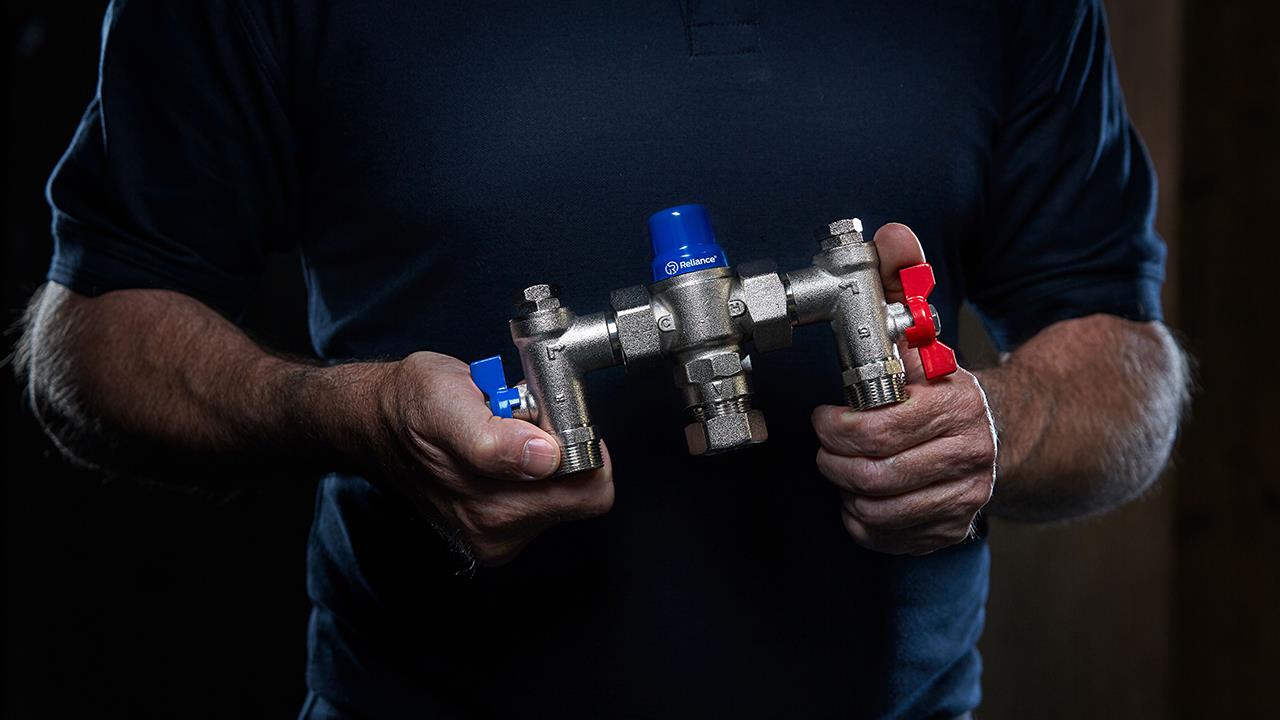

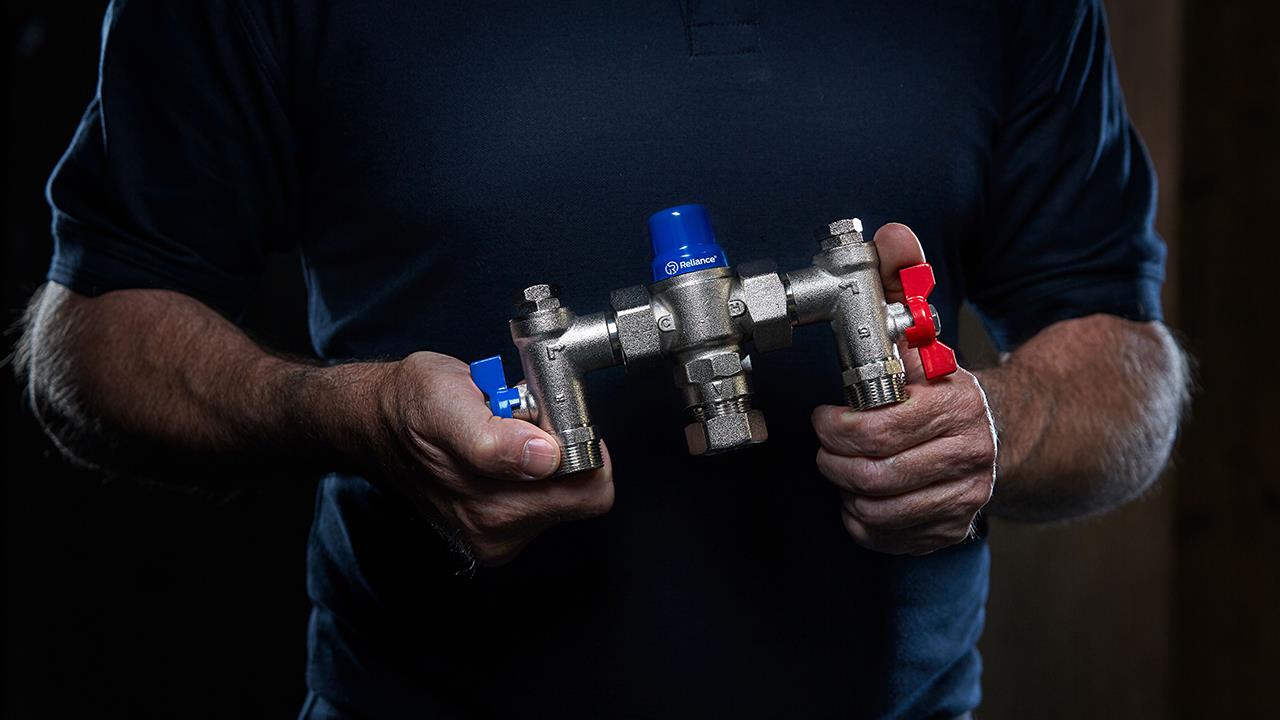

Let’s talk about TMVs – thermostatic mixing valves. TMVs reduce the risk of scalding by safely blending hot and cold water, while allowing hot water systems to run at a high enough temperature to prevent Legionella bacteria from breeding.

TMVs are regulated by law. It is a legal requirement to install TMVs in all commercial and domestic newbuilds, healthcare settings, and properties undergoing a ‘change of use’.

As an installer, your main concern will be around fitting the right valve for the right application and ensuring it is fit for purpose. Here is what you should know.

Location is key

TMVs should be installed as close to the outlet as possible. This limits the amount of mixed water between the valve and the outlet and ensures that water can be distributed at temperatures above 65ºC to help stop Legionella bacteria breeding.

When using one valve for multiple outlets, also known as group mixing, and common in commercial applications under the TMV2 scheme, the TMV must be able to achieve the same set temperature at the closest serving outlet as the furthest (within -2°C). It is important the valve is located as centrally to those outlets as possible.

The distance from the TMV to the outlets should not exceed 2m to limit any stagnation points.

Under the TMV3 scheme, group mixing is not permitted. The valve should be fitted no further than 2m from the serving outlet, however it is recommended to install it as close as possible.

Size matters

It is vital that the TMV is sized correctly, for the demand required. This ensures mixed water is delivered at a constant and accurate set temperature – whether one outlet is being used or multiple.

By referencing the given application’s water pressure against the valves set flow rate, you can ensure that the valve size is correct for the job. This information can often be found within the valves technical data sheet or installation guide.

Expert product and technical advice

To identify the correct TMV for your installation, your first point of call is to check the requirements of the application and ensure they match those set out within the manufacturers’ technical specifications.

With ongoing updates to regulations and products, it can be invaluable to speak to someone who knows TMVs like the back of their hand. Connect with us on reliancevalves.com/support and we can help you select the right TMV from the start.

In our next column, we will explore regulations and best practice for maintaining TMVs.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.