To start, let’s explore the difference between buildings with and without mechanical ventilation with heat recovery (MVHR).

A building without MVHR: heated indoor air escapes outside, and fresh incoming air must be continuously heated.

A building with MVHR: warm air from inside the building is passed through a heat exchanger in the AHU, transferring its heat to incoming fresh air.

The components of an MVHR system include:

Ducts

Supply ducts deliver fresh outdoor air into the building via the Air Handling Unit (AHU). Extract ducts remove stale indoor air, passing it through the AHU before exhausting it outside.

Heat exchanger

The heat exchanger, central to an MVHR system, transfers heat from outgoing warm air to incoming cold air, using thin walls to separate the air streams without allowing them to mix.

Filters

Filters are present on both the supply and extract sides. They purify incoming air by removing pollutants and protect the heat exchanger by filtering out particles from the extracted air.

Fans

An MVHR system includes two fans, one each for supplying and extracting air.

Vents

Intake vents draw fresh outdoor air into a building's ventilation system, while exhaust vents expel stale indoor air, together ensuring a continuous supply of clean air.

Grilles

Supply grilles distribute conditioned air throughout a building, while extract grilles remove stale air.

MVHR’s two major benefits

Energy efficiency

An MVHR system works on a straightforward yet effective principle: it uses the energy from outgoing, warm air to heat the incoming fresh air, thereby reducing the energy required from the building's heating system.

MVHR systems significantly reduce emissions and energy usage by utilising waste heat that would otherwise be vented out.

Indoor air quality

Sustainable buildings are not just about environmental impact; they are equally about creating healthier living and working spaces. Indoor air quality is a significant aspect.

An MVHR system continuously supplies fresh, filtered air into the building while extracting stale air, contributing to better indoor air quality.

The design process for an MVHR system

Define the requirements

When designing an MVHR system, it's crucial to understand the local standards and regulations governing building ventilation.

These standards, which vary by region, help you to determine the system's requirements.

Locate the air handling unit (AHU)

The placement of the AHU impacts the system for a range of reasons. It needs to be accessible, centrally located, structurally sound, and sensitive to noise.

Define the intake and exhaust points

Intake vents should be positioned away from pollution sources, while exhaust vents should be placed to prevent re-circulation of expelled air.

Locate the supply and extract grilles

Plan the supply and extract grilles placement to ensure uniform air distribution.

Supply grilles should be located to distribute fresh air evenly, and extract grilles should be situated in areas with higher moisture or pollutant levels, like bathrooms.

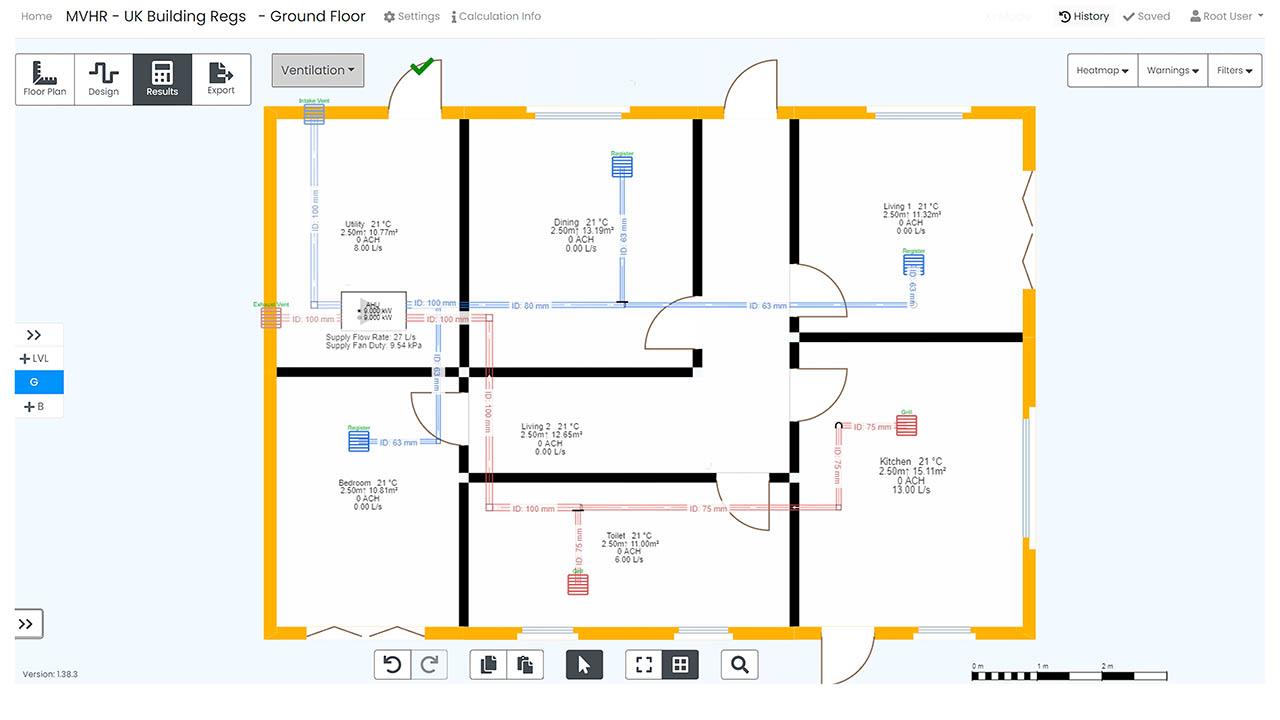

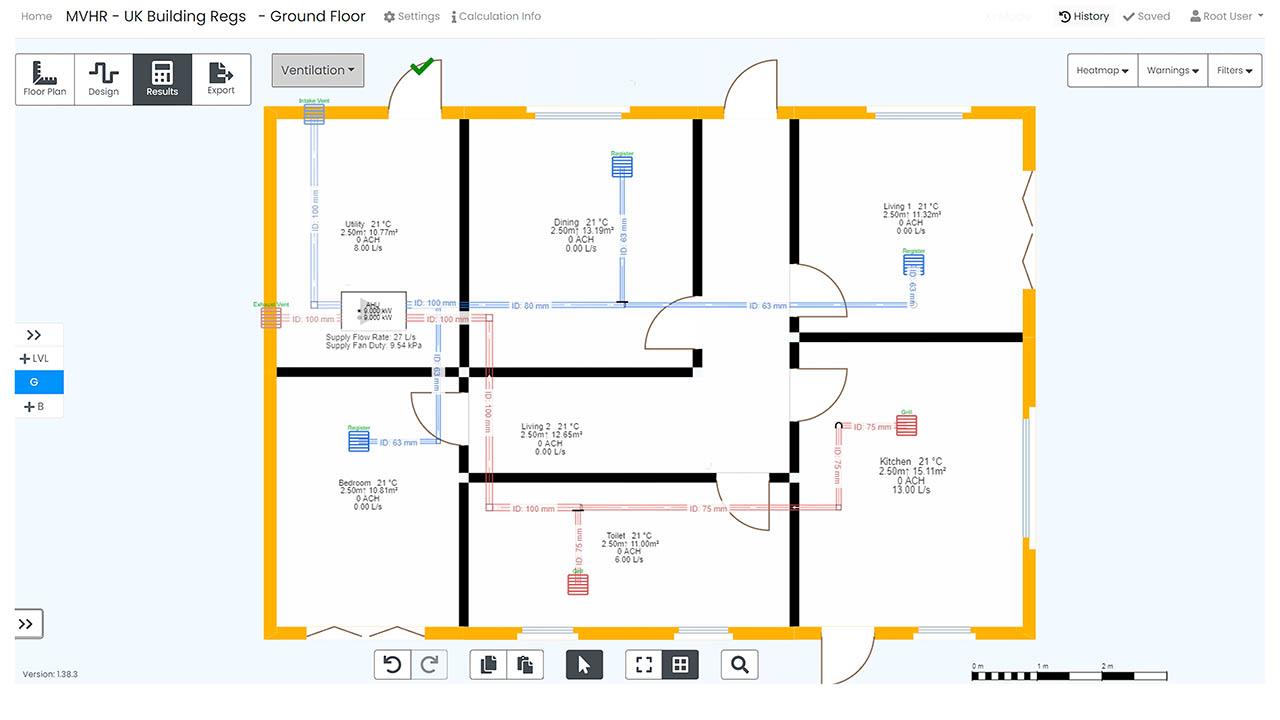

Draw the ductwork layout

Design the ductwork to connect the system efficiently.

The layout should minimise duct lengths and bends to optimise system performance.

Size the system

Firstly, determine the required airflow rate based on the local standard’s requirements - this could be the building's size, number of rooms, or occupancy levels,

Then, size each component of the system, including ducts, vents, and the AHU, based on this flow rate and the layout.

Accurate sizing is critical for the system's performance as it influences the effectiveness of ventilation and energy consumption.

MVHR energy saving calculation example

#1 - Determine the Annual Ventilation Heat Requirements

Hourly Ventilation Heat Loss: 0.7 kWh

Heating Degree Days: 2,240

Annual Ventilation Heat Loss = 0.7 kWh * 2,240

Annual Ventilation Heat Loss = 1,568 kWh/year

#2 - Calculate the Heat Requirements for MVHR

MVHR System Efficiency: 90%

Heat Requirement = Ventilation Heat Loss * 10% (as the system recovers 90%)

Heat Requirement = 1,568 kWh/year * 10%

Heat Requirement = 156.8 kWh/year

#3 - Calculate energy savings

Recovered Heat = Ventilation Heat Loss * System Efficiency

Recovered Heat = 1 kWh/year * 90% = 1,411.2 kWh/year

Energy Savings = 1,411.2 kWh/year

MVHR system payback period calculation example

#1 - Determine the Initial Investment Cost

Cost of MVHR System: £4,000

Installation Cost: £1,500

Total Initial Investment = £5,500

#2 - Determine the value of the energy savings

Annual Energy Savings: 1411.2 kWh

Energy Cost: £0.29/kWh

Annual Financial Savings: 1411.2 kWh * £0.29/kWh

Annual Financial Savings = £409.25

#3 - Calculate the payback period

Payback Period = Initial Investment / Annual Savings

Payback Period = £5,500 /£409.25/year

Payback Period = 13.4 years

To learn more about MVHR, you can download the eBook ‘Mechanical Ventilation with Heat Recovery (MVHR) System - A Comprehensive Design Guide for Beginners’ from h2x’s website.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.