Neil Macdonald, Technical Manager at the Heating and Hotwater Industry Council (HHIC), outlines the importance of water treatment to maximise performance of low temperature heating systems.

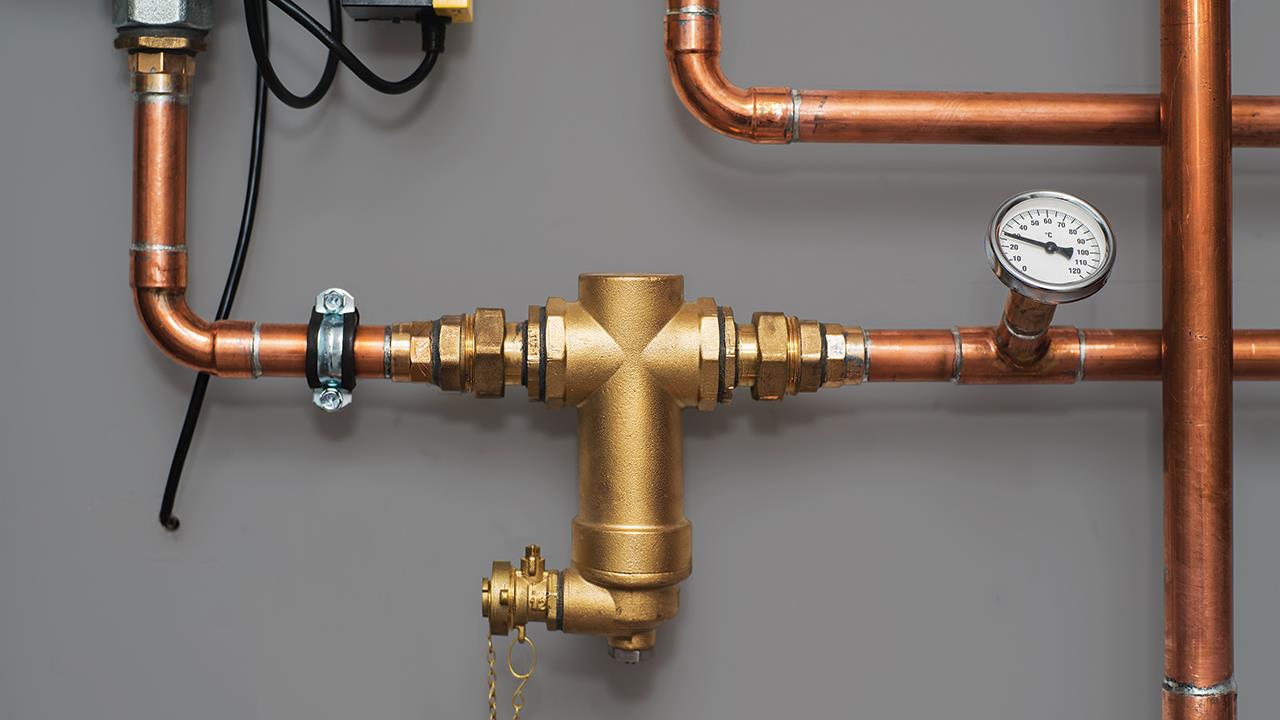

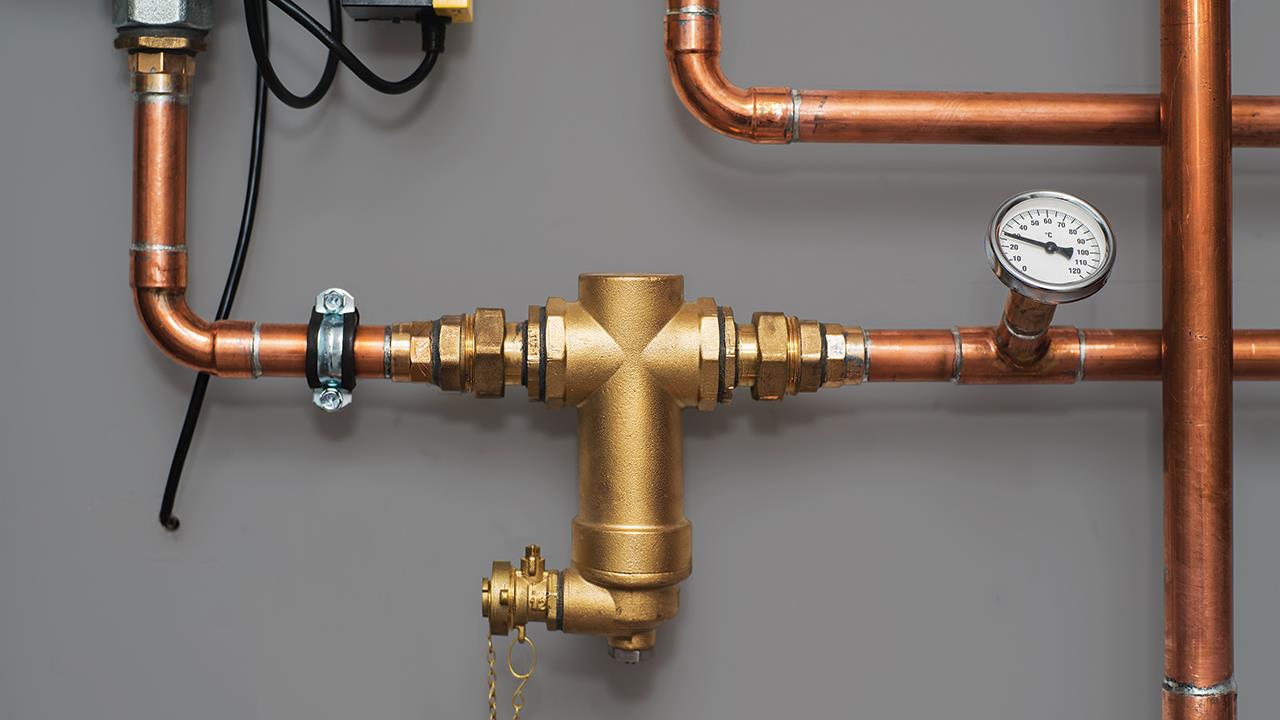

As the UK continues to head towards a more sustainable heating future, the prevalence of ultra-efficient and low temperature heating systems, such as those fed by heat pumps, will increase. To protect and maintain the performance and longevity of these systems, effective water treatment is critical.

Low temperature systems

‘True’ low temperature systems are often defined as heating systems that operate between 35°C and 45°C. When we consider that the historical norm for boiler flow temperatures is 82°C, then flow temperatures below 55°C (much discussed under Part L proposals) can also be seen to be low, or at least lower temperature systems.

Low temperature systems frequently also operate at lower system temperature differentials, which are characterised by higher flow rates, and system pressure drops. This means that any system restrictions or internal surface linings caused by deteriorating water quality and resultant corrosion, such as magnetite sludge, can be particularly problematic, and cause the system to underperform or, in the worst case, break down.

It is important that the industry is informing and reminding end-users about the need for effective water treatment for all hydronic heating systems, such as heat pump or boiler-fed, and embedding this as standard practice.

From 2025, perhaps sooner once the Future Homes Standard is implemented, homes built to the new standard will realistically need to make use of some kind of low carbon heating, and an associated low temperature system. Future policy for existing dwellings may well follow a similar theme, therefore continuing to develop the necessary installer competence in this area is crucial.

Water treatment

The Domestic Building Services Compliance Guide to Part L of the Building Regulations in England stipulates the rules for water treatment, and cross-references the main standard in these matters for domestic heating systems, BS 7593.

Part L is currently under review, but from the consultation text of the draft Approved Document L, it is clear that system cleansing, flushing, and the addition of a suitable inhibitor upon final fill, remain the minimum standard, where ‘presumption of conformity’ is concerned.

When a system is originally installed and commissioned, the installer must dose the system with the correct concentration of inhibitor to water upon final filling, as dilution of the product to concentrations below the optimum level may place the system at greater risk from magnetite sludge, and other forms of corrosion. The details must then be recorded on the digital Benchmark record, or Benchmark commissioning checklist, and left with the user.

This means that both the installer and, if they need to, the consumer, are able to quickly and easily identify the incumbent inhibitor. This is important, as established industry guidance is not to mix different inhibitors, to ensure that the active ‘ingredients’ in different formulations do not work against each other in any way. Testing the concentration of system inhibitor should then be an annual process, as advocated by BS 7593.

Hydronic balancing

Low temperature heating systems typically produce less convective heat, and while rooms will be heated to a design temperature (as with all system designs), they rely on the end-user’s perception of heat to achieve comfort.

Where a system is characterised by lower mean water temperatures in the emitters then, without uniform heating across the dwelling, it is possible that this might be more obvious to the consumer, as they begin to feel cold. As such, it is vital to rule out any balancing issues with low temperature systems, and this should be in addition to effective water treatment practices.

Hydronic balancing of the system, when undertaken correctly, will ensure even distribution of heat from the outset. An unbalanced system can cause cold and/or hot spots to emerge in a house, or cause the property to not heat at all. Ultimately, if a system is not adequately balanced, its efficiency is significantly reduced.

Working together

It is important that correct water treatment remains at the forefront of industry thinking, so that breakdown and performance issues can be avoided. This is even more critical as we move more widely to low temperature, low carbon heating systems, and seek to win the necessary battle for consumer hearts and minds, if we are to reach our net-zero goals.

Preventable failures can undermine consumer faith in the robustness and reliability of these systems, and their typically connected heating technologies, such as heat pumps. This is why the HHIC, its water treatment group, and indeed wider membership, are all working together to provide the highest levels of industry support and collaboration around effective water treatment.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.