Paul Millard, Technical Manager at the Water Regulations Advisory Scheme (WRAS), explains the vital role that Reduced Pressure Zone valves play, and what the new WRAS Approved Installation Method means for installers at the end of the transition period.

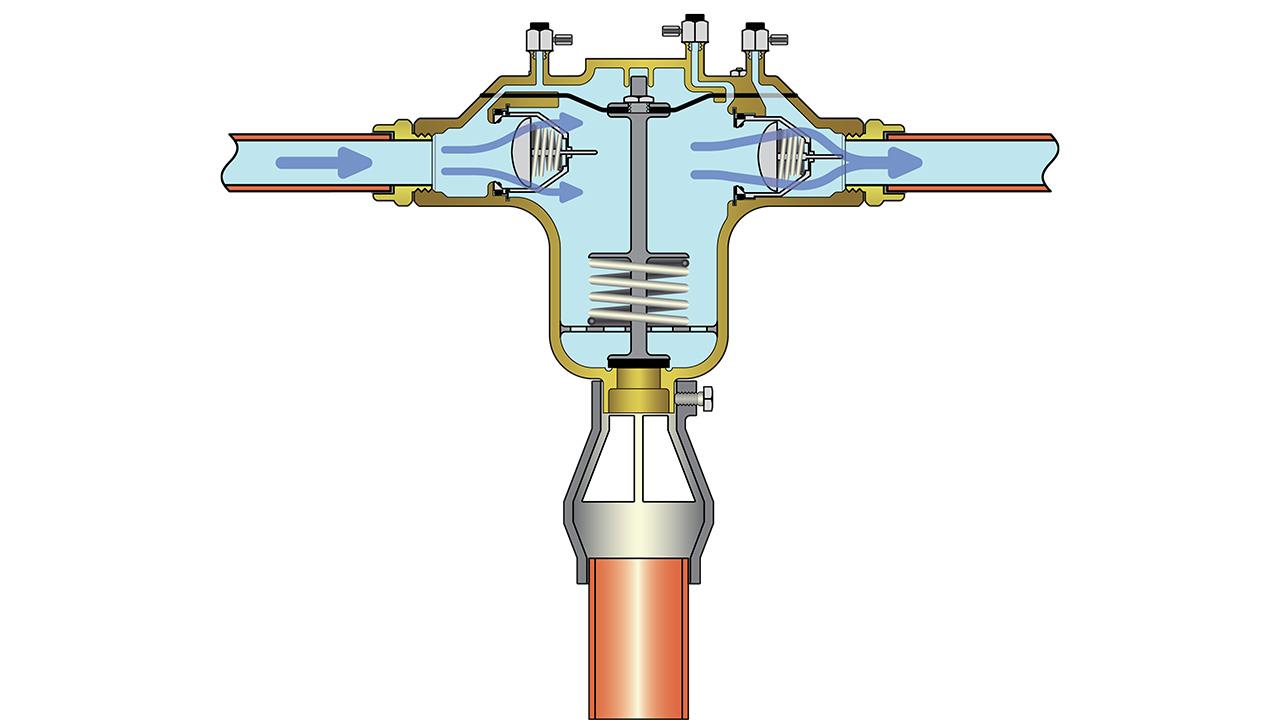

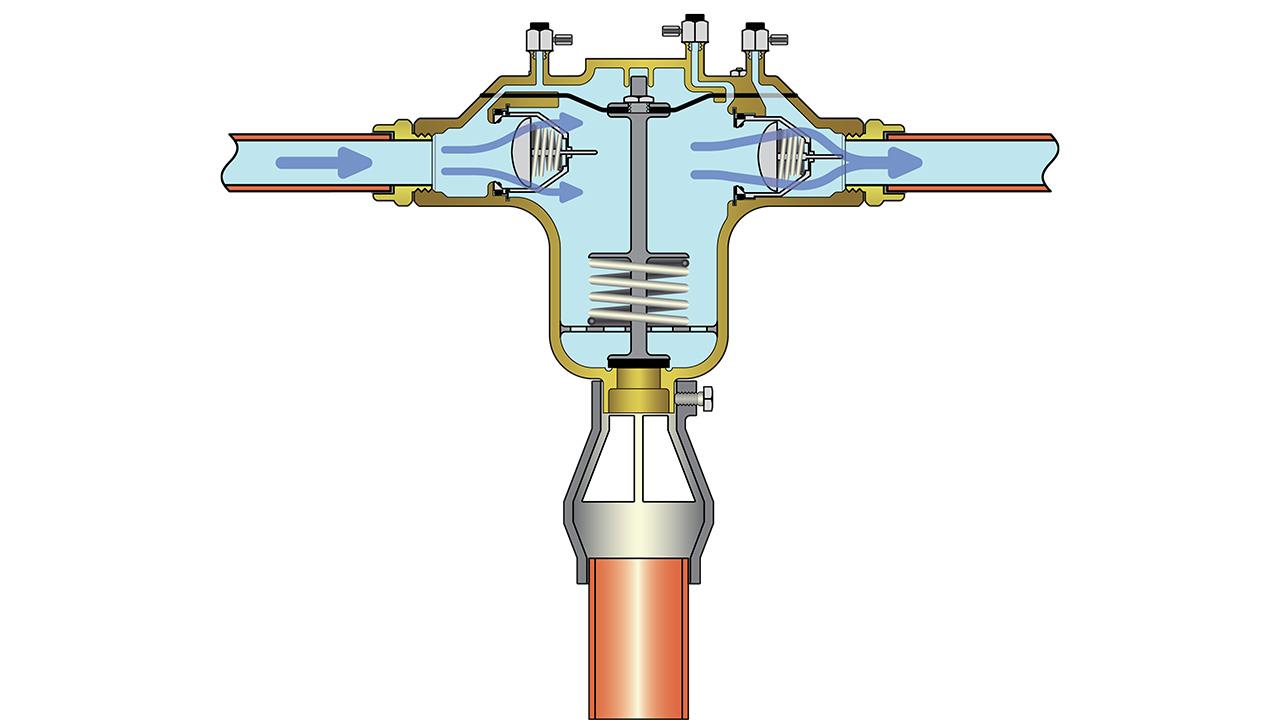

Reduced Pressure Zone (RPZ) valves, the common name for Type BA devices, play an important role in helping to protect people from contamination and can be one of the safest backflow prevention devices, providing that the correct maintenance and testing is routinely undertaken.

RPZ valves, unlike other backflow preventions, must be tested annually by an approved tester to ensure they are fit for purpose, protecting against the water supply potentially becoming contaminated.

In January 2020, WRAS confirmed changes to the Approved Installation Method (AIM) for Type BA devices following a comprehensive review by the water industry, which concluded in a new AIM being published. The AIM (Issue 2 of AIM 08-01) has been updated to ensure that commissioning and testing is carried out consistently to a suitable standard.

The publication saw the start of a 12-month transition period allowing installers and users to become familiar with the updated requirements and give time for RPZ testers to access the necessary training. 7 January marked the end of this period, meaning that Issue 1 of the RPZ Aim 08-01 has now been withdrawn and is no longer recognised by water companies who enforce the water fittings regulations and byelaws. But, what does that mean for plumbers and installers?

What changes have been made?

The installation or alteration of RPZ valves must be notified to the local water company and must adhere to the Water Industry Approved Installation Method (AIM 08-01). Issue 2 of AIM 08-01 details the standards for commissioning and compliance testing RPZ valves, as well as ensuring test equipment is calibrated while helping improve how tests are reported.

In terms of the changes to the AIM 08-01, it is important to know that notification requirements have not changed and remain an important element. The notification process can ensure RPZ valves are suitable for the proposed application, before purchase, as they can often be expensive.

An important part of notification to highlight is the consent notice issued by the water company, as this contains important information and conditions which need to be followed closely.

There have been changes to the installation requirements. For example, to ensure it can be easily accessed for testing, the maximum height of an RPZ valve is 1.5m, measured from the floor to the top of the valve. There must also be clearance underneath the valve to maintain air gap protection (at least 0.3m) for the relief port.

In addition, the updated AIM now includes information on commissioning and a field test for compliance testing. It is important to note that while these terms are new, the physical testing remains the same. Any commissioning or testing must only be completed by a competent person, for example a trained and approved RPZ Valve Tester, after it has been installed.

Within the updated AIM, a clearer explanation has been provided for the roles and responsibility for managing RPZ valves, in particular with regards to reporting and what should happen if the RPZ valve fails the compliance testing. Where there is a failure which cannot be immediately repaired, water companies will need to be consulted and agree the remedial actions. This will ensure consumers be protected.

What does this mean for RPZ testers?

With the transition period now over, any RPZ testers who have not taken the conversion training to familiarise themselves with the changes, will no longer be recognised by water companies.

These testers will now have to sit a full training course based on Issue 2 of the AIM through a commercial training provider. These courses must include up-to-date information on the new AIM and its requirements. Once testers have completed the training they can join an approved RPZ tester scheme, such as the RPZ Valve Tester sector within WIAPS, TAPS, APLUS, WaterMark, and SNIPEF will also be running schemes too.

Details about suitable training courses can be found from the schemes’ websites. At the time of writing, WIAPS and WaterMark have opened their schemes and are accepting membership applications, with the remaining schemes planning to do so soon.

The New Year is a time when many people review their needs for the coming year. So, now is the perfect time for all plumbers and installers to ensure they are fully up to date with any training, regulations, and requirements that can help to keep clients safe and compliant.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.