David Pittilla, National Technical Manager at Myson Controls, explains why heating controls are a perfect match for underfloor heating.

While radiators remain the most common type of heat emitter seen in UK homes, there is a growing number of homes heated by underfloor heating so it makes sense for all installers to be familiar with the differences in controls that are needed.

Underfloor heating (UFH) has been around for centuries – we all know that it dates back to Roman times, although it is fair to say that the technology has certainly progressed since those times. Essentially the same principles still apply, which is to heat the floor mass and then let the heat transfer in a wonderfully uniform way to create a comfortable environment with no hot or cold spots.

One significant benefit, and a reason that these systems are becoming more common, is that they operate at low temperatures with water entering the floor can as low as 45°C, with a return temperature of 38°C. This means that a UFH system is futureproof – it is able to meet increasing low energy standards by allowing modern gas boilers to operate at higher efficiencies, as well as compatible with future low temperature heating technologies without the need for future resizing.

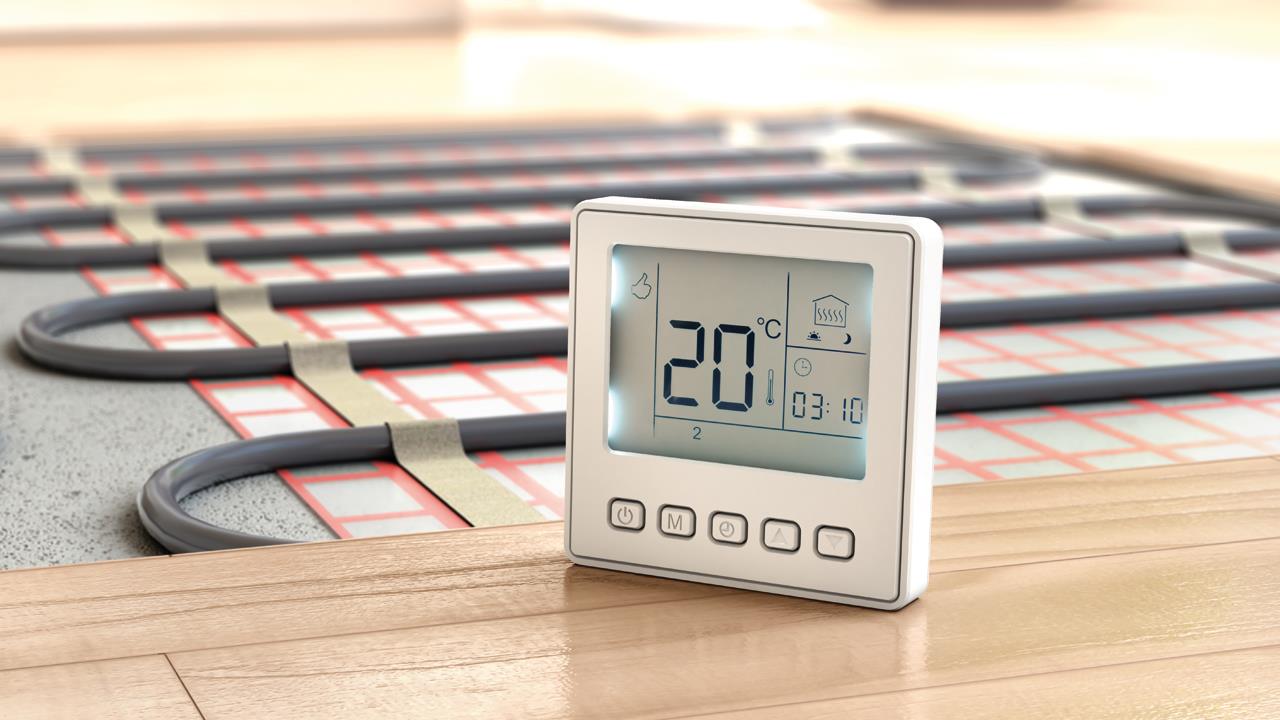

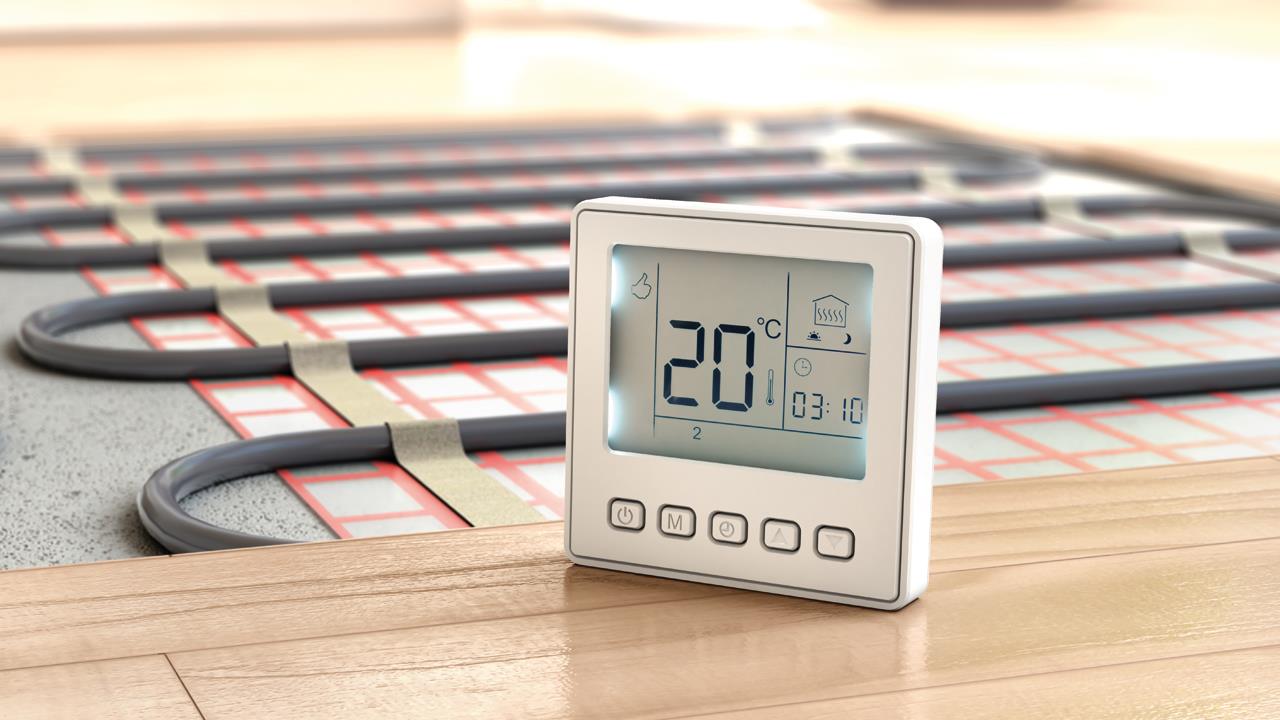

Control of UFH systems uses technologies that will be familiar to anyone who works on a boiler and radiator system, though applied slightly differently. Part L of the Building Regulations says UFH systems in all rooms should have their own thermostat or programmable room thermostat, and provide a boiler interlock, so heat isn’t generated when there’s no requirement.

Modern room thermostats can sense how fast each room approaches temperature and then tailor the heat provided into the room to maintain relatively uniform comfort conditions. These thermostats can also be internet enabled so you can control each room in your property remotely, so you only use heat as and when you need it.

UFH can also be integrated with existing traditional heat emission systems, such as radiators/towel warmers/fan convectors etc. The simple addition of a blending valve can simply convert a high temperature heat generator system into one that can incorporate a low temperature UFH system.

So, UFH is a highly effective heat emission solution that is efficient, compatible with both high and low temperature systems, futureproof, and can be incorporated into virtually every type of building structure.

If you'd like to keep up-to-date with the latest developments in the heating and plumbing industry, why not subscribe to our weekly newsletters? Just click the button below and you can ensure all the latest industry news and new product information lands in your inbox every week.